The Australian Auto Industry is in Jeopardy

When I think of Australian cars, my thoughts immediately go to the likes of the Holden Commodore/Calais/Caprice and Ford Falcon, and all of their related derivatives. Then the next thought that comes to mind is a tricked-out HSV-fortified Maloo R8 (pictured here) with its 6.2 liter LS3 V8 underhood. They’re charming cars, and fun to drive (at least the old Pontiac G8 version of the Commodore was). Unfortunately, they’re also dinosaurs in a world where small displacement, forced induction, and front wheel drive is the norm.

Global realities are catching up with the local Australian auto industry. Buyers don’t want the types of cars locally produced in Australia (aside from the thousands of people who buy Toyotas – which unseated Holden as the country’s best-selling brand a few years ago). Thanks to the influence of Mark Reuss, Holden produces Cruze compacts locally (including the not-for-the-US hatchback model) – a move that may have at least staved off the inevitable for a few years.

Currently, three global manufacturers still build cars in Australia following the departure of Mitsubishi in 2008 amidst slumping demand. Australia’s new-car market is about a tenth of the size of the US market, and even without Mitsubishi, it has more production capacity than its local market can support. Some of that production is exported, some is sold domestically, and the rest of the capacity sits unused.

Toyota has a reputation for doing whatever it can to keep its people fully employed despite market conditions. Nevertheless, it is cutting 350 of its 4,600 employees at its Melbourne plant that builds the Camry, Camry Hybrid, and Aurion. Toyota has seen its local production decline from a high of 149,000 units back in the good old days to a projection of 95,000 units in 2012. Toyota sold 181,624 cars in Australia in 2011, but obviously a sizable chunk of those were imported from elsewhere.

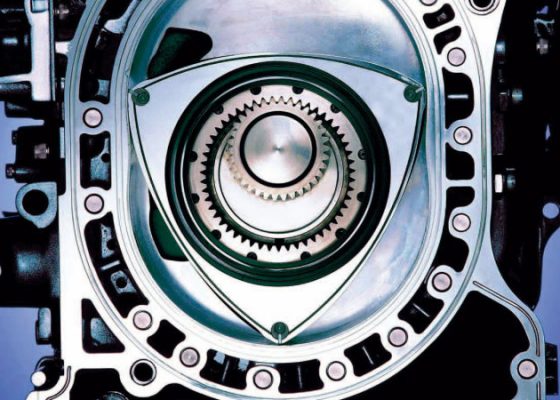

GM’s Holden subsidiary served as the engineering basis for GM’s global rear drive architecture (also known as Zeta), which underpins the Commodore and friends, as well as the all-American (and Canadian-built) Camaro. But guess who engineered the latest GM rear wheel drive architecture, Alpha, which underpins the new Cadillac ATS and likely some other future products? Not Holden – it was engineered in the US. According to one of our sources, there will be no more major engineering done at Holden. The VF – which is the successor to the current VE model – will likely be the last full engineering program done in Australia by Holden, which is also confirmed here. Going forward, Holden’s engineers will be responsible for ensuring that global vehicles will fit local markets. Reading between the lines of a press release on Holden’s media site entitled, “Renewed Focus on Aussie Car Industry,” the government wants to keep the engineering work there, but GM executives quoted have committed to production and noted that “there was unprecedented competition for capital investment in manufacturing and product development for next generation global vehicles.” Reading further between the lines, it sounds like if Australia comes up with some super-sweet enticements and incentive packages, they might consider keeping some engineering work Down Under.

Ford is going in a similar direction with its Ford Australia subsidiary as well, going to global architectures that don’t have a place for the type of vehicle that the Australian auto industry has typically specialized in. A few weeks ago, the rear wheel drive Falcon received a five year stay of execution from Ford, meaning it will be produced through 2016. The Falcon will get some enhancements for 2014, but it will continue to soldier on with its 2002-vintage underpinnings. After 2016, its inline-six will have trouble meeting strict Euro V emission standards, and will require substantial investment – something that Ford may not be keen to do under “One Ford.” Expect to see a 2017 Falcon based on a global front wheel drive architecture with optional all wheel drive, probably similar to a future Taurus.

Ford is going in a similar direction with its Ford Australia subsidiary as well, going to global architectures that don’t have a place for the type of vehicle that the Australian auto industry has typically specialized in. A few weeks ago, the rear wheel drive Falcon received a five year stay of execution from Ford, meaning it will be produced through 2016. The Falcon will get some enhancements for 2014, but it will continue to soldier on with its 2002-vintage underpinnings. After 2016, its inline-six will have trouble meeting strict Euro V emission standards, and will require substantial investment – something that Ford may not be keen to do under “One Ford.” Expect to see a 2017 Falcon based on a global front wheel drive architecture with optional all wheel drive, probably similar to a future Taurus.

Part of the business case for developing the VE platform, which would spawn the G8, was that exports to the US could top 50,000 units. G8 sales never did that well, and the fleet-only Caprice PPV (police patrol vehicle), exported from Australia to the US, is thus far selling in only token numbers. Just 99 units in December 2011 and 880 throughout all of 2011 while the car was available to law enforcement agencies to purchase.

The Sydney Morning Herald reported over the weekend on how, given Toyota’s latest announcement, economists are questioning whether it makes sense for Australian policymakers to support an industry that cannot stand on its own. According to the SMH article, the manufacturing industry in Australia received some $6.5 billion AUD in tariff assistance in 2009-2010 and another $2 billion AUD in subsidies. The question is whether that money would be better spent elsewhere, if anywhere.

It’s worth pointing out that Australia is far from the only country to provide tariff or subsidy assistance to its manufacturing industry, or even to its auto industry. Does the word “bailout” mean anything to you in the context of the US auto industry? Then there is currency manipulation in Japan – and its auto industry crying uncle as the government in Tokyo has to balance demands for intervention from the automakers against charges of currency manipulation from its trading partners, specifically the US.

Also, we should point out that the auto industry is under a fairly grave threat in more places than just Australia. The UK no longer has much of a domestic auto industry, unless you count Indian-owned Jaguars and Land Rovers, or BMW-owned MINIs. Japan’s auto market has been contracting for the better part of a decade, and its big players are actively making plans to shift production to lower-cost countries, including the US. Then there’s the mess in Europe, with the continent likely to slide into recession (if not already there) on the back of government near-defaults – and even before the European debt crisis really boiled over, there was a very well-known overcapacity problem in Europe that unions, politicians, and industry executives refuse the face the hard realities of the need to close plants and eliminate jobs. Closing plants and eliminating jobs, by the way, is one reason the US industry is back on its feet, relatively speaking (not to mention the convenience of having far, far less debt on the books than before bankruptcy).

Residing in a country with a domestic auto industry – particularly one that has the capability to design, engineer, and build a vehicle using domestic talent and resources alone – is a source of national pride for Australians. There are only 13 countries in the world today in which this is even possible. With the more recent news, things are indeed looking bleak in Australia. While production will likely continue for some time, and the same brands will probably remain in place there all but forever, the longer-term future of vehicle production in a high-cost country is a shaky proposition.

So what’s the answer? Policymakers in Australia have to face a few stark choices:

- Provide ever-richer incentives to automakers to continue to maintain engineering and production in Australia,

- Adjust the tariff scheme to improve the competitiveness of the industry while not angering trading partners OR protecting them so much that they’re not competitive,

- Re-train former auto-industry workers so that they can move on to a growing, more future-proof industry, while accepting that the coming industry job losses will happen.

None of the options are particularly attractive, but the current state is not particularly sustainable. If you were in charge of setting manufacturing policy for Australia, what would you do to preserve its auto industry? Anything at all? Let us know in the comments below.